PRODUCTS

About Baopack

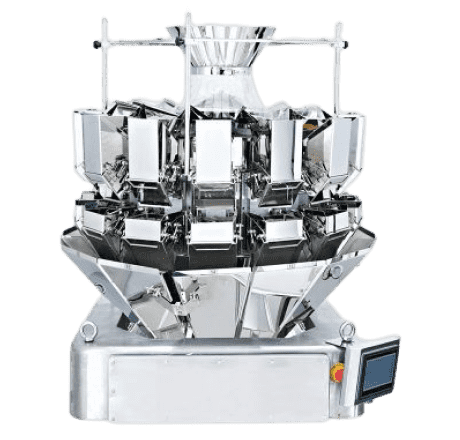

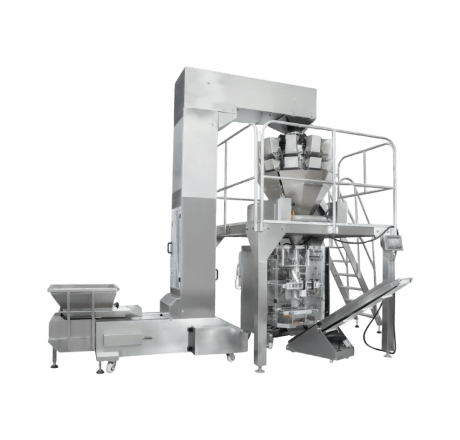

Founded in 2001, Baopack is located on Beiyuan East Road, Shishan Industrial Park, Nanhai, Foshan City, Guangdong Province. It has a modern standard factory with a construction area of about 30,000 square meters. Baopack focuses on the research and development of automatic measuring machines, automatic packaging machines and automatic packaging lines, and is a high-tech enterprise integrating R&D, manufacturing, sales and after-sales service. Currently, Baopack has developed more than 20 series of machines and produced more than 50 models of automatic packaging machines. With excellent performance, leading technology, simple operation, easy maintenance, safety and durability, Baopack has become a predominant automatic packaging machinery company. Our automatic packaging machines are widely used in food industries, agricultural products, pharmaceuticals, hardware products and other fields that meet considerable customers’ needs.

R&D Capability

We believe that R&D is crucial to the innovation of automatic packaging machines, so we will update the required technical means from time to time. The R&D process is so crucial in BAOPACK that our R&D department is personally supervised by the department head.

The innovations that BAOPACK has continuously provided to the market over the years are the result of our investment in research and development. From our company’s R&D team, we can see how much our company attaches importance to R&D. They enjoy the process of developing new products, and this spirit can lead BAOPACK to a higher level.

Production

The company always checks every process of production and pursues no mistakes in every link. The manufacturing of each machine is carried out step by step according to the plan to ensure a smooth production process.

Quality

The quality of BAOPACK is in the leading position in the automatic packaging machine industry, and the company arranges technicians to inspect the entire production process of the machine. In addition, there is professional production personnel to check the quality of the machine so that the quality of each machine can satisfy customers.

Services

All our machines provide a one-year warranty period and provide customer-satisfied after-sales service after the machine is sold. Different technicians will be sent to solve problems online and offline according to after-sales problems so that customers can use and buy our machines with peace of mind.

Professional Automatic Packaging Machine Solutions

Get A QuoteBecome Our Machinery Strategic Cooperative Dealer

Become A Dealer

You get a partner with over 30 years of experience designing, manufacturing, integrating and servicing the world's most advanced automatic packaging solutions.

On the subject of service, BAOPACK works together. Our target is to provide our customers with consistent support. Reachability, fast availability and a worldwide team of competent service engineers guarantee perfect service for your economic success.

-

29-10-2025

29-10-2025Efficient and Reliable Solutions for Salt, Nuts, and Frozen Dumplings Packing

In the modern food processing industry, efficient packaging solutions are essential for maintaining product quality and meeting consumer demands. Salt packing machines, nuts packing machines, and frozen dumplings packing machines are indispensable tools for manufacturers looking to streamline their production processes while ensuring consistent packaging standards. Salt packing machines are... -

29-10-2025

29-10-2025High-Performance Biscuits, Lollipop, and Ketchup Packing Machines for Modern Food Production

When it comes to modern food packaging, efficiency and precision are essential. Biscuits, lollipops, and ketchup are some of the most commonly consumed products, and ensuring they reach consumers in perfect condition requires advanced machinery. Biscuits packing machines, lollipop packing machines, and ketchup packing machines have become indispensable tools in... -

23-10-2025

23-10-2025Efficient Liquid Filling and Packing Machines for Modern Production

Maintaining product quality and efficiency is crucial in liquid packaging industries. Baopack Machinery offers a comprehensive range of liquid filling and packing machines designed for precise, fast, and reliable operations. These machines cater to diverse applications, including beverages, dairy products, oils, and chemical liquids, helping manufacturers streamline their production lines...

Partner Links

If there is anything you're not sure about or you just need a hand getting set-up you can call or email us.