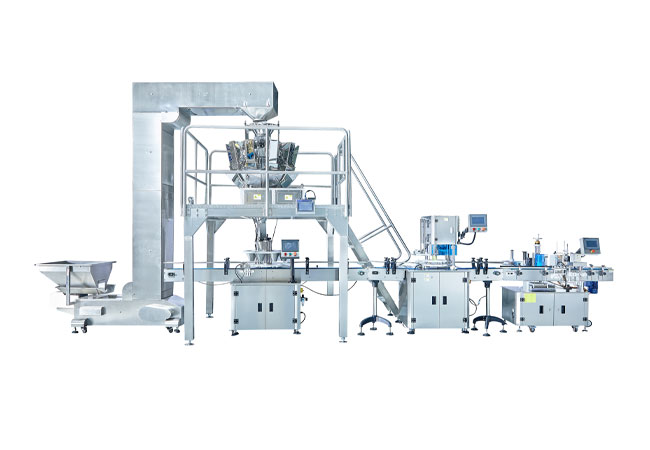

Full Auto Can Packaging Line

Feature

- The overall appearance material is mainly made of stainless steel 304, with a thickness of 1.5mm.

- The chuck and receiving hopper need to be replaced to replace the blanking caliber. The replacement and debugging time is about 10 minutes.

- To change the height of the jar, no need to change accessories, just shake the hand wheel, the range is controlled by 50-200mm.

- The turntable type receiving and filling machine is mainly used in combination with a combination scale. For the situation of small can mouth and large materials, the filling turntable has multiple stations to buffer the synchronous vibration during feeding, which can increase the filling speed and prevent material blocking.

- The operation of this machine requires an air compressor, please purchase it separately, and an air compressor above 3KW is required.

Parameter

|

Model |

CB-JL130 |

|

Control Panel |

7 inch LCD monitor |

|

Filling Diameter |

φ40~φ130mm, applicable height 50~200mm (customized according to the can size) |

|

Turntable Station |

10 stations (the design may be changed according to the actual situation) |

|

Speed |

30-50 cans per minute |

|

Power |

AC 220 V, 50Hz, 0.95KW |

|

Air Consumption |

about 2 cubic meters per minute 0.6-0.8Mpa, air source or air pump is used as auxiliary equipment, and relevant auxiliary equipment needs to be prepared by yourself. |

|

Dimension |

2200 * 1100 * 1500mm |

|

Height of the Conveyor Belt from the Ground |

900mm |

|

Width of the Chain Belt |

114mm (the size can be customized if required) |

|

Weight |

Net weight 200kg |

Optional

8 Head Liquid Filling Machine

Automatic Slitting Capping Machine

Can Seamer

Double Head Liquid Filling Machine

Inkjet Printer

Labeling Machine

Powder Filling Machine

Round Table Type Filling Station

Sorting Machine